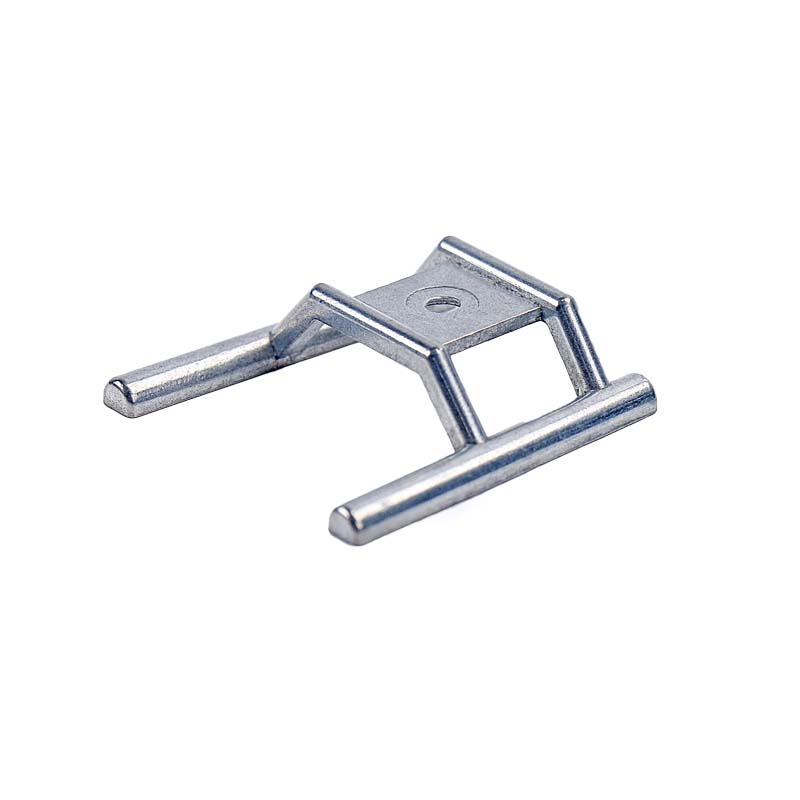

In this case, we demonstrate our ability to manufacture custom zinc alloy die-cast components tailored for the automotive industry. These small and intricate parts are often used in structural connectors, fastening supports, and interior hardware, requiring both mechanical strength and dimensional accuracy.

Our team worked with an automotive client to produce zinc components for various internal assembly functions. Although the final application remains confidential, this project showcases our experience in dealing with small yet high-demand zinc parts at scale.

The client required:

Small zinc alloy components with consistent dimensions

Durable material with good corrosion resistance

High-volume production capability with stable quality

Clean, burr-free finishes suitable for visible or functional surfaces

The parts were small and geometrically detailed

Dimensional consistency was critical across batches

Required a uniform surface finish for aesthetic and assembly purposes

Tooling design needed to optimize cycle time and reduce defects

Custom Mold Design: Optimized for high-volume zinc die casting

Precision Casting Parameters: To control part shrinkage and surface flatness

Post-Casting Finishing: Included deburring, shot blasting, and optional plating

In-Line Inspection: Ensured critical dimensions were maintained across runs

Successfully delivered small automotive-grade parts with ±0.05 mm accuracy

Reduced post-processing with clean as-cast surface quality

Achieved excellent consistency across thousands of units

The client was impressed with speed, finish, and reliability

Our experience in zinc die casting for the automotive sector ensures we can support clients with high-precision, high-volume miniature components. Whether you’re developing new auto parts or replacing legacy components, our engineering and production team can bring your vision into reality.

In-house tooling and design optimization

Cost-effective mass production capability

ISO-compliant process control

Fast turnaround and consistent results